⚙️ DC Motor Speed Control (Arduino + L293N)

A microcontroller-based system to control a 12V DC motor using PWM with two programmable speed patterns—ideal for industrial motion control and automation labs.

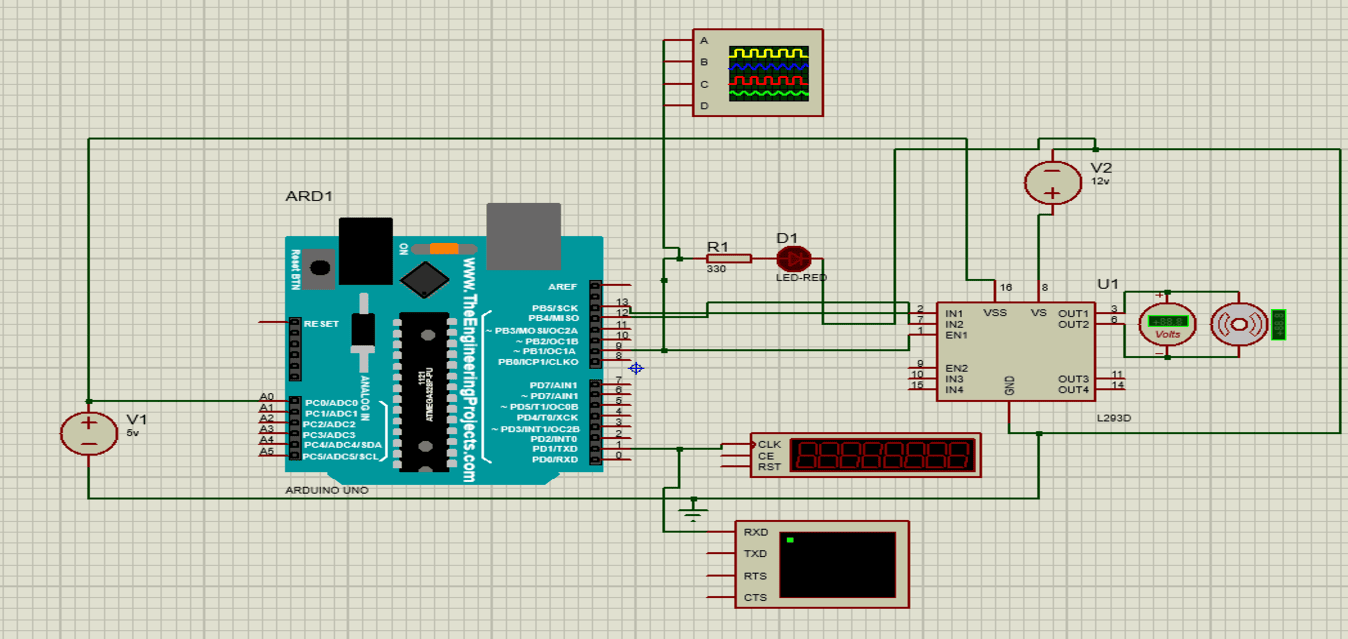

Circuit & Simulations

🎯 Objectives

Design and implement a microcontroller-based system that operates a DC motor with varying and constant speeds based on defined timing patterns, simulating industrial processes where precise speed control is critical.

🧩 Problem Description

Pattern 1 — Smooth Ramp

- Gradually increase speed to maximum within 1.5 minutes.

- Gradually decrease speed back to zero within the next 1.5 minutes.

- Turn OFF the motor.

Pattern 2 — Step-wise Doubling

- Slow speed for 30s → double for 30s → double again for 30s.

- Reduce speed in reverse order with the same delays.

- Turn OFF the motor.

🛠️ System Description

- Microcontroller: Arduino Uno (ATmega328P) — 8-bit MCU with 6 PWM channels.

- Motor Driver: L293N H-bridge — bidirectional control with PWM speed control.

- Motor: 12V brushed DC motor, continuous rotation, PWM capable.

- Power: 12V DC for motor, 5V regulated for Arduino.

- Software: Arduino IDE (development) and Proteus (simulation).

| Arduino Pin | Motor Driver Pin | Function |

|---|---|---|

| D9 (ENA) | ENA | PWM signal for speed control |

| D13 (IN1) | IN1 | Motor direction control |

| D12 (IN2) | IN2 | Motor direction control |

| GND | GND | Common ground |

| 5V | Vcc (logic) | Logic power (if required) |

💻 Arduino Source Code

// Arduino Code for DC Motor Control

const int ENA = 9; // PWM pin for speed control

const int IN1 = 13; // Direction control

const int IN2 = 12; // Direction control

// Speed parameters (PWM values 0-255)

const int speed1 = 50; // Minimum speed to overcome friction

const int speed2 = 255; // Maximum speed

void setup() {

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

// Initial direction (forward)

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

Serial.begin(9600);

}

void loop() {

Serial.println("Pattern 1:");

Pattern1();

delay(5000); // Pause between patterns

Serial.println("Pattern 2:");

Pattern2();

delay(5000); // Pause before repeating

}

void printSpeed(int speed) {

analogWrite(ENA, speed);

Serial.print("Speed set to: ");

Serial.print(speed);

Serial.print(" (");

Serial.print(map(speed, 0, 255, 0, 100));

Serial.println("%)");

}

// Pattern 1: Constant acceleration and deceleration

void Pattern1() {

const unsigned long rtime = 90000; // 1.5 minutes in ms

const int steps = 100;

// Ramp up

for (int i = 0; i <= steps; i++) {

int speed = map(i, 0, steps, speed1, speed2);

printSpeed(speed);

delay(rtime / steps);

}

// Ramp down

for (int i = steps; i >= 0; i--) {

int speed = map(i, 0, steps, speed1, speed2);

printSpeed(speed);

delay(rtime / steps);

}

// Turn off

printSpeed(0);

Serial.println("Motor OFF");

}

// Pattern 2: Double speed every 30s

void Pattern2() {

const unsigned long sTime = 30000; // 30 seconds

int baseSpeed = 60; // ~25% of max

int speedLevels[] = { baseSpeed, baseSpeed*2, baseSpeed*4, baseSpeed*2, baseSpeed, 0 };

for (int i = 0; i < 6; i++) {

printSpeed(speedLevels[i]);

Serial.print("Step "); Serial.print(i + 1);

Serial.print(" - Speed: "); Serial.println(speedLevels[i]);

delay(sTime);

}

Serial.println("Motor OFF");

}📈 Simulation Results

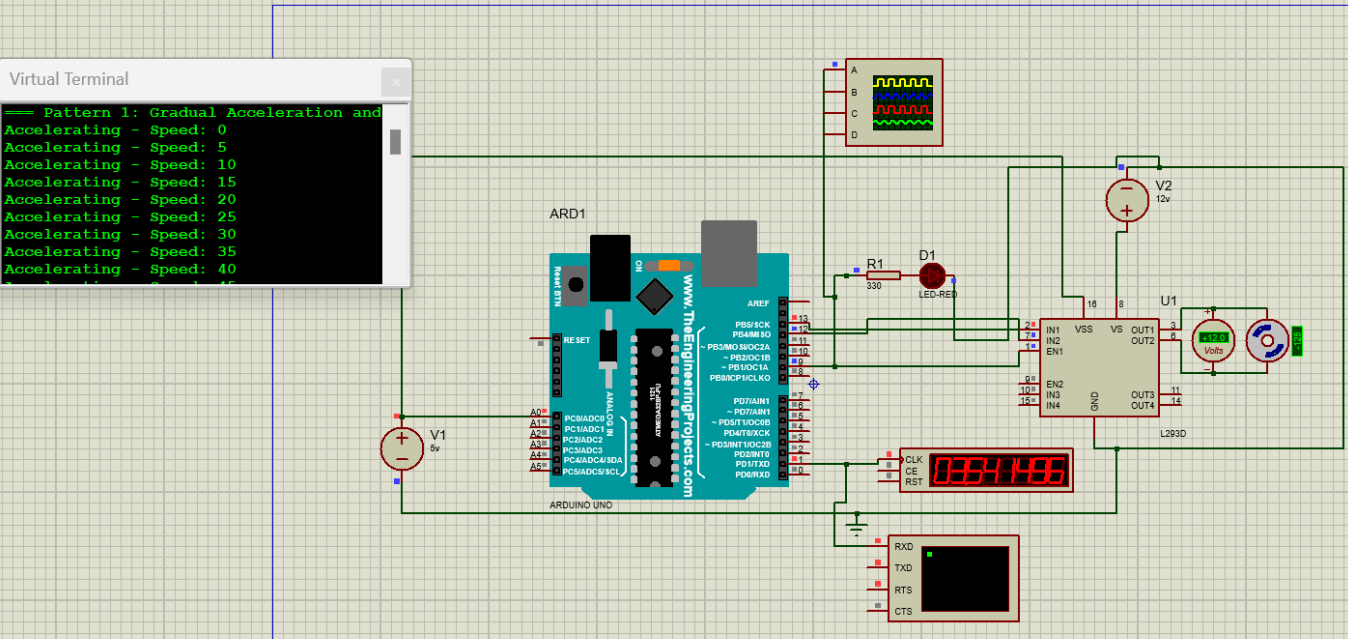

- Pattern 1: Smooth acceleration to peak over 90s and symmetric deceleration to zero.

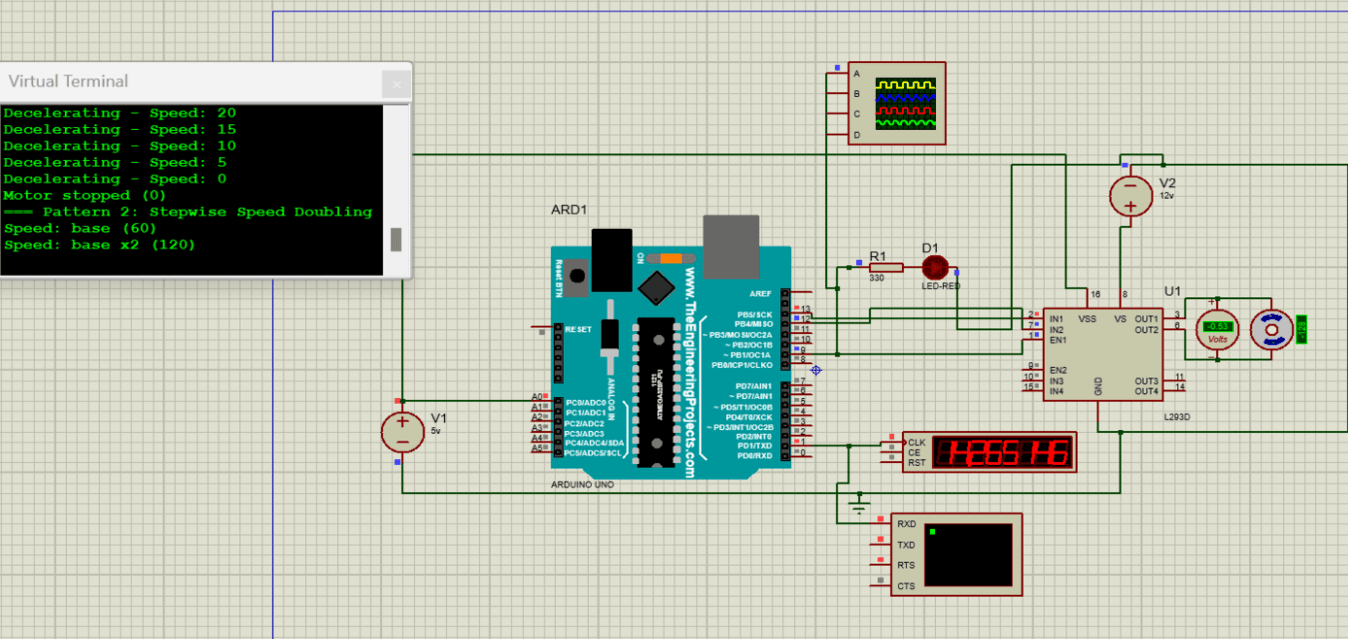

- Pattern 2: Step-wise speed doubling every 30s, then mirrored down to OFF.

🌍 Importance & Use Cases

This controller demonstrates techniques used in conveyors, pumps, fans, and process lines, where precise speed profiles reduce mechanical stress, improve throughput, and enable repeatable automation cycles.

🔗 Repository

MIT Licensed — Feel free to use, modify, and improve. ⭐ the repo if this helped!